HZ-2 Filament Special Slurry Powder

Category: Product Center

Summary:HZ-2 has super strong adhesion to polyester fibers and glass fibers, and its excellent film-forming properties play an important role in protecting warp yarns, saving 20%-30% of the cost compared to acrylic. If it is used as a surface coating to increase the surface hardness, it can meet different stiffness requirements.

Make An InquiryProduct Detail

Performance parameters:

| Product name | MW | glass transition temperature | Intrinsic Viscosity | Acid value (mg/g) | weight | Appearance | smell | Aqueous |

| HZ-2 | 10000-12000 | 10-50℃ | 0.45dl | <5 | 1.36 | Yellow particles | odorless | 0.5% |

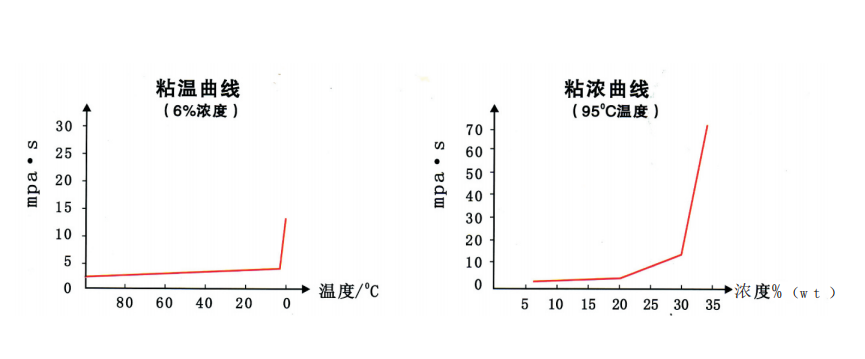

Performance Curve:

1. Low viscosity: use penetration to obtain a suitable sizing rate

2. The viscosity is stable with temperature and concentration: keep the slurry performance consistent

New paste features:

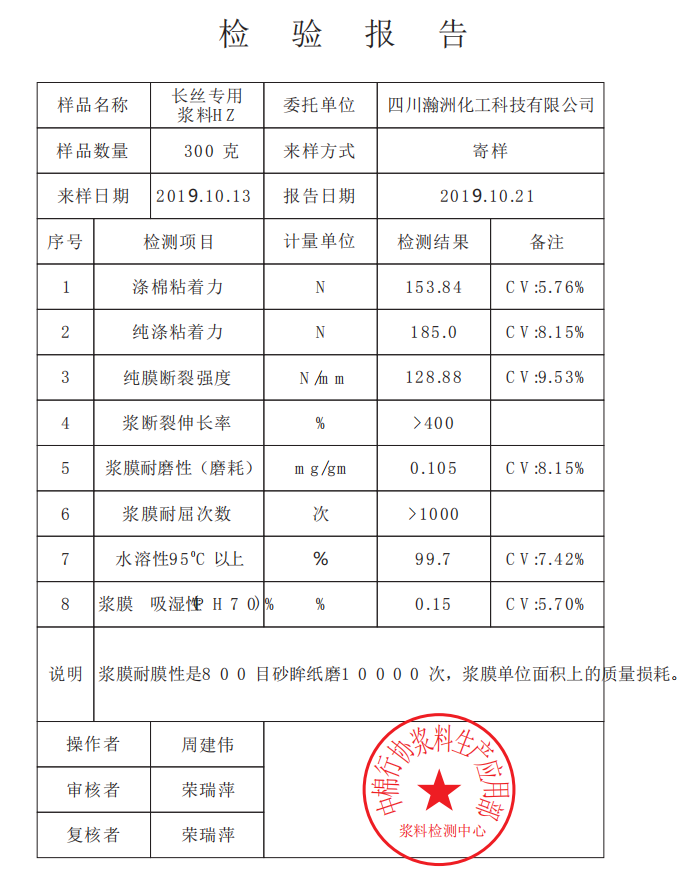

Excellent adhesion

It has super adhesion to polyester fiber and glass fiber, and its excellent film-forming properties play an important role in protecting warp yarns, saving 20%-30% of the cost compared to acrylic. If it is used as a surface coating to increase the surface hardness, it can meet different stiffness requirements.

Drying performance

Easy to dry, 15%-20% faster than acrylic.

Excellent permeability

Due to the low viscosity of the prepared slurry, the penetration is very good, and it can be sizing at room temperature, thus saving energy.

Moderately hygroscopic

No re-viscosity, the moisture absorption of the serous film is less than 0.5% when the relative humidity is 70%.

High molecular weight

The sizing film is flexible and has excellent adhesion to polyester fibers, and the sizing film is smooth, complete and wear-resistant.

Good environmental performance

Can be hydrolyzed, acid-base degradation, photolysis. Not only the degradation performance is good, but also the dosage is small, and the impact on the environment is small. BOD/COD > 0.3 detected by Sichuan Environmental Testing Center.

Reduce costs

Due to the super strong adhesion and excellent film-forming properties of HZ, the dosage is relatively reduced, effectively reducing the production cost by 40%-50%.

Packaging and Storage:

1. Kraft paper-plastic film composite packaging, net weight 25kg per bag.

2. Store in a cool and ventilated place.

3. Strictly prevent moisture, exposure, and high temperature to avoid agglomeration.

Instructions for use:

1. Sizing

Compared with the concentration of acrylic acid, the concentration can be appropriately reduced.

(1) At room temperature, put an appropriate amount of water in the mixing bucket according to the concentration required by the user, and start stirring once to add the raw materials.

(2) Stir well, heat up to boiling, and then simmer at a constant temperature for more than 60 minutes, until the slurry is completely completely dissolved.

(3) Cool down to 600 C, then add an appropriate amount of additives and stir evenly, then filter with a filter screen of more than 200 meshes and put it into a clean storage bucket, Store capped.

2. Dissolve

(1) The sizing temperature is controlled at room temperature.

(2) Because the size is easy to dry, the drying temperature for sizing is slightly lower than that of acrylic.

(3) Due to the strong adhesion of the new type of paste, the sizing rate can be appropriately reduced compared to the original (acrylic paste).

3. Sizing

4. Desizing method

Add an appropriate amount of sodium hydroxide with pure water, then add an appropriate amount of dispersant and heat it to above 95°C.

Note: (1) When the temperature is greater than 950C, it must be stirred and boiled for more than 60 minutes to completely dissolve the product, otherwise the viscosity of the slurry will easily increase several times; it cannot be stored in a high temperature pot for a long time, otherwise It is easy to damage the pulp, resulting in poor permeability of the pulp, and causing the pulp wire to stick and break.

(2) After adding the auxiliary materials, it must be filtered with a 200-mesh filter screen. It is necessary to add multiple filter screens on the pulper. Otherwise, some impurities will be brought into the pulp wire, and the pulp wire will be broken when the shaft is combined. .

Keywords: HZ-2 Filament Special Slurry Powder

Related Products

Online Inquiry